In my job, I have been working with climatic chambers. Of course, I will not design one but I am curious about how it works, like every engineer that interacts with such a complex system would be. I had some estimations on how it heats, cools, and humidifies the environment but I bumped at dehumidification. How does it do that? Therefore, I decided to research the chambers from fundamentals to fine details.

Let’s start with what is a climatic chamber. It is a testing system that can create extreme environments by setting temperature and humidity. According to requirements of the product, it may generate rainforest environments by adjusting 50C temperature and %75RH, or extreme cold -40C like Alaska. Of course, it depends on the system specifications but to sum up, that’s it.

The first function, controlling temperature, is the simpler one. It does it by the most common heat-exchanging method: convection. Actually, air of the environment passes through the actuators of two systems, cooling coil and re-heater resistance.

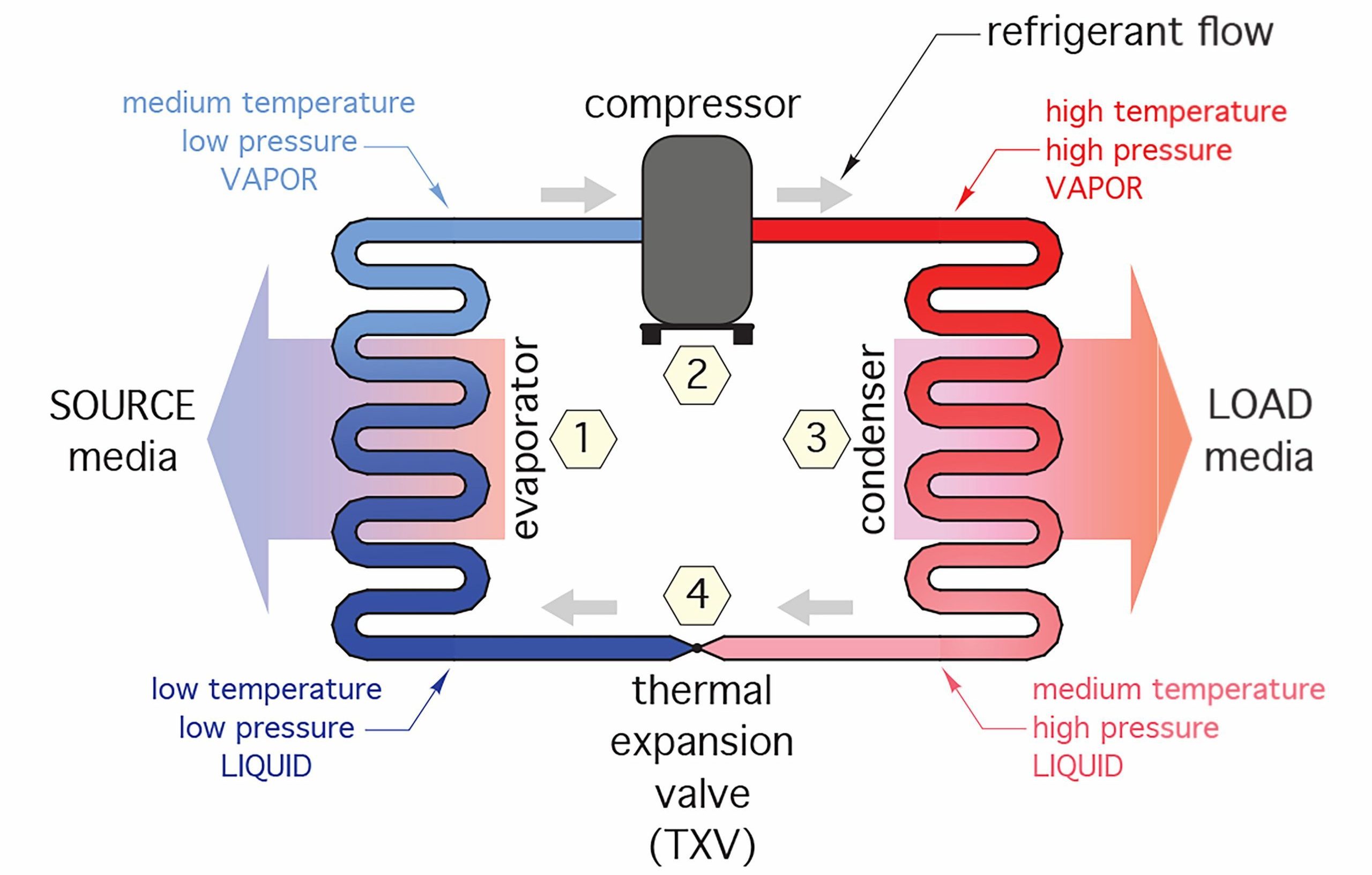

The first system is a refrigeration cycle which includes evaporator/cooling coil, compressor, condenser and expansion valve. Firstly, the refrigerant fluid in the coil takes heat from the air by evaporating. Then, the vapor goes into the condenser and this component cools and transforms it to liquid form again. Afterwards, the expansion valve makes the liquid even colder with a significant drop that originates from expansion. Finally, the refrigerant fluid that becomes extremely cold goes into the coil and the cycle continues.

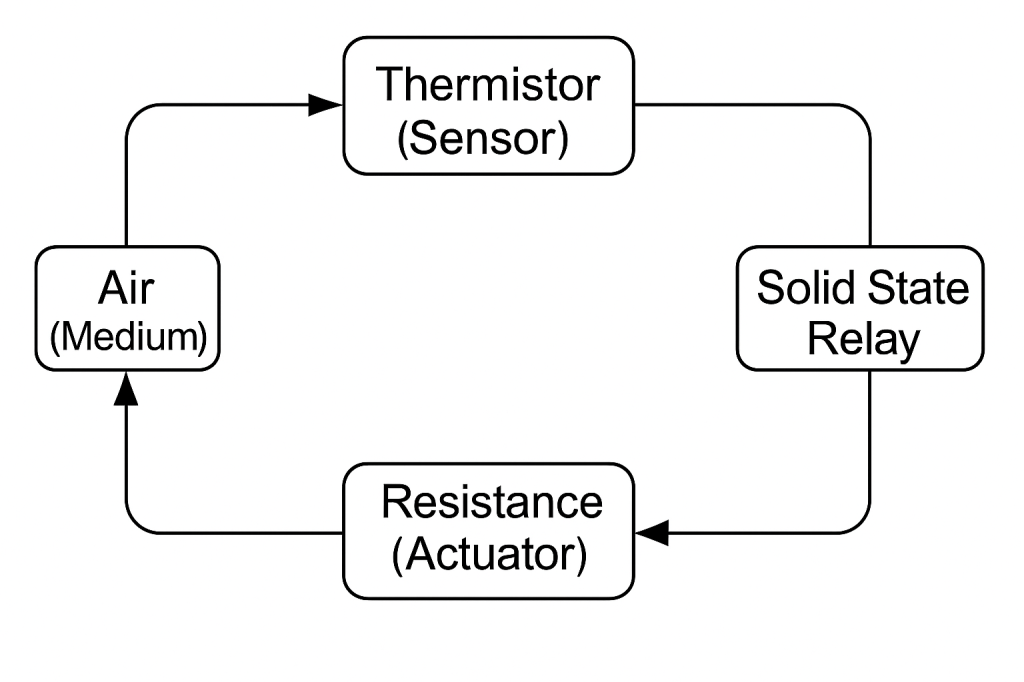

The second system is a simple closed-loop control system. The resistance, which is the actuator, heats the air; the solid state relay, which is the controller, adjusts the resistance according to the feedback from thermistor or which sensor is used for measuring temperature.

According to purpose, heating or cooling, the systems work collaboratively. If the duty is cooling, the first system cools the air as much as possible and the re-heat system stabilizes to the set temperature. If vice versa, only the second system works to make air reach the target temperature.

The second function, controlling humidity, is complex because dehumidification is made in indirect or advanced ways. For this part to make sense, firstly, I should explain the temperature-humidity relation.

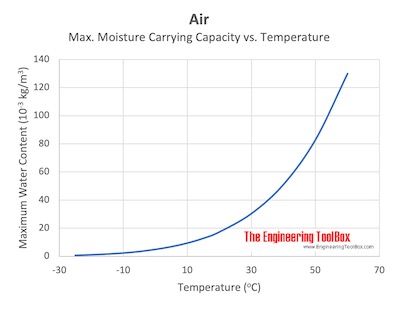

Air can hold an amount of water in gas form, which is called absolute humidity. Because pressure and amount are proportional and if the pressure reaches the saturation pressure, it begins to transform into liquid phase, which is called condensation. So higher saturation pressure means higher absolute humidity capacity. The saturation pressure and temperature are also directly proportional. You could have already put the pieces together, but in summary, the parameter that will change the amount of water that can be held by air is the temperature.

Before the process, I should explain another concept: relative humidity. This is a commoner term that is used for humidity publicly. It is the ratio of the amount of vapor that exists in air to the maximum amount of vapor that can be held by the air, and it is generally represented by RH.

The most common way of dehumidification is indirect control by temperature which is built on the principles that I explained above. The refrigeration system cools the air to lose its excess vapor by condensation until the target value. Then, the re-heat system heats the system until desired conditions.

The advanced but less common way is using moisture-retaining materials. Silica gel, lithium chloride, and zeolite are examples of that kind of material and these are like sponges, sucking the vapor in molecular level. If I try to explain this, the article will be too long. Let these materials be the subject of another article 😀

On the contrary of dehumidification, humidification is easy. Water is boiled and steam is released directly into the air. There are various technologies like ultrasonic humidification, spray atomizer, etc. but they differ in efficiency, sensitivity or capacity. Simply, all of them boil and release the vapor.

In conclusion, the climatic chambers are the test systems that control specific environmental conditions: temperature and humidity. They are designed on basic thermodynamic principles:

- Zeroth law of thermodynamics (thermal equilibrium) in heat transfer between the air and the fluid or re-heater resistance

- Expansion causes pressure drops so the temperature drops in the expansion valve.

- Absolute humidity capacity ɑ Saturation Pressure ɑ Temperature

Is a more efficient way possible?

Leave a comment